Remove RFQ Item

New Products Catalog

Remove RFQ Item

Back

The 2018 Symposium on Application Technologies of New Materials and Processes for Automotive Chassis was successfully held in Hefei from October 18 to 20. This event brought together integrated supply chains including vehicle manufacturers, component suppliers, and raw material providers to comprehensively evaluate and guide the development of lightweight automotive chassis. In response to national energy-saving, emission-reduction, and consumption-lowering policies, as well as China’s 2025 emission requirements, regions across the country are actively implementing these initiatives.

As a specially invited guest, Wuhu hetian Automotive Industry represented component manufacturers in a presentation. Our topic "Application of Aluminum Alloy Forgings in Automotive Chassis" gained widespread industry recognition and facilitated extensive exchanges with vehicle manufacturers and raw material suppliers.

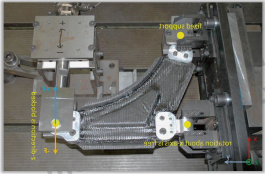

Requirements for energy-saving, emission reduction, and consumption reduction are increasingly stringent, while electric vehicle range demands grow stricter. Vehicle manufacturers’ calls for chassis lightweighting are intensifying. As component suppliers, we play a pivotal role in this ecosystem. Some peers have even begun researching lightweight chassis products such as carbon fiber control arms and knuckles, aluminum alloy subframes (see image below), aluminum alloy brake calipers, and magnesium-aluminum alloy wheels, conducting comprehensive R&D across new materials, processes, and technologies.

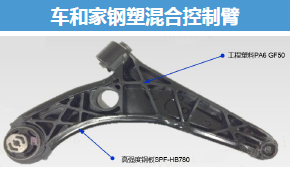

Although hetian holds significant standing in aluminum forgings, competition remains fierce. Prototypes like carbon fiber control arms and steel-plastic hybrid control arms have already emerged. Even at the prototype stage, they represent a revolutionary technological advancement.

Lightweighting is an interdisciplinary field driving modern automotive technology. While aluminum forgings have made outstanding contributions to chassis lightweighting, our advantages diminish as the industry evolves (new processes, materials, and technologies). This phase presents both opportunities and challenges for hetian. We must maintain a "crisis mindset" – continuing to leverage our strengths while learning from industry innovations. Complacency is not an option.

The journey toward establishing China’s automotive chassis lightweighting capabilities is long and demanding. We must guard against complacency and forge ahead with perseverance!

Technology Department --- Zhao Yingjun